In the present day

scenario, as for any other industry, the most pressing need in the textile

industry is to create sustainable solutions that help in the conservation of

resources to the greatest extent possible. A feasible way to ensure that

resources are conserved is to gauge the textile manufacturing process

meticulously and pin-pointing the areas where there is some potential to

initiate savings. Since energy, water and additives are the major components

that go into the manufacturing

of textiles, it

is the saving of these very elements that matter the most. In this regard, the

Resource Calculator has come off as a major relief.

Tuesday 8 December 2015

Sunday 29 November 2015

Benefits of Digital Textile Printing

Digital Printing

in context of textiles refers to a printing method whereby a digital image is

printed directly to a fabric, or cloth material. Here, the dye-sublimation

printer executes the process of printing through the use of heat in order to

transfer the dye on the printing medium. Simply put, once the design is created

and finalized, and uploaded on the printer, the process of printing becomes as

seamless as that on paper. The digital textile printing

is a technique that is quickly picking up, due to its ease of use and other

significant benefits, the most important of which are discussed below.

|

|

|

Saturday 21 November 2015

Textile Industry Welcomes Extension Of Export Benefit

The textile industry of India has been facing a

major blow, one of the worst in its history, pertaining to the slowdown that

hit the global textile and clothing markets in April 2014. Due the termination

of region FTA by other competing nations, exports from India have encountered

an all-time low owing to its tariff barriers, expensive cotton, high fibre

price and the unprecedented delay in the pay-out of the TUF subsidies. Given

the scenario, the industry had long been demanding the extension of additional

incentives through the Merchandise Export from India Scheme (MEIS). The demand

also pressed for a grant of 3% interest with respect to the export of all

textile merchandise, at least till the time that the exports reach their

projected potential growth.

|

|

|

Saturday 14 November 2015

Reinvent Domestic Textile through Dyeing

What does one do when domestic

textiles such as clothes and apparels, bed sheets or curtains grow out of

fashion, or simply old? While throwing these away or changing them with new

ones are the alternatives most usually taken, one way to deal with them can be

by reinventing them into something totally different, simply by the way of

dyeing.

|

|

|

Friday 6 November 2015

Nano-Filtration - An Effective Way For Textile Effluent Treatment

The 21st

century has brought upon the global textile industry, the urgent need to reduce

the water wastage, pertaining to the manufacturing process. This need has been

further pressed by the fact that regulations on the discharge of effluent have

been tightened all across the globe. Textile as an industry expels humongous amounts of water as waste, which makes it

essential for it to find out some feasible production techniques, which in turn

helps the industry meet the regulatory standards.

|

|

|

Thursday 29 October 2015

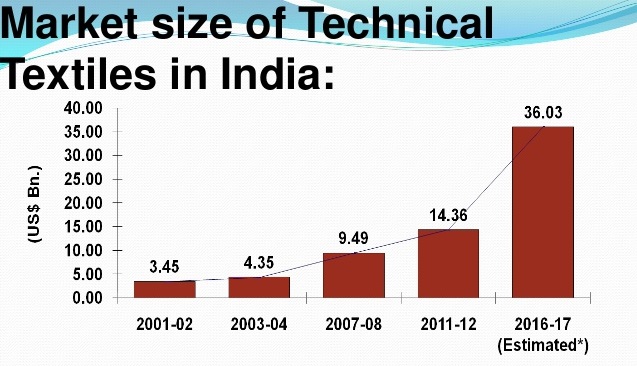

20 Percent Annual Growth Expected In Technical Textile Industry.

Technical Textiles, as you may already know are nothing but the textile products manufactured for purposes other than aesthetic. These include the textiles required for application in automotive, medical textiles, agro-textiles, as well as those required for making protective clothing, such as spacesuits, bulletproof vests, or that worn by the fire-fighters and welders etc. Technical textiles also include materials and products used for their technical performance and functional properties such as tyre cords, airbags, industrial textiles, furniture lining, tents, parachutes etc.

|

|

|

Friday 23 October 2015

Repo Rate Cut Welcomed By Textile Industry

To

begin with, Repo Rate is precisely the rate at which the Central Bank of the

country lends money to all commercial banks during the event of shortage of

funds.

In

a recent financial move the RBI Governor, Dr. Raghuram Rajan

announced a cutback on the current repo rate from 7.25 percent to 6.75 percent,

which was brought into effect immediately on 29th September, 2015.

This repo rate deduction of 50 basis points has been more than welcomed by the textile industry of the country, simply for the

reason that this cut will majorly benefit capital-intensive industries.

|

|

|

Subscribe to:

Posts (Atom)